OEM SERVICES – Your Complete Eyewear Solution

Eyewear Design Process

Ⅰ. Trend Research & Needs Analysis

• Market Scanning: Analyze WGSN/Pantone color trends (200+ seasonal designs annually)

• User Profiling: Match ergonomic database with regional preferences (e.g., EU/Asia fit)

• Competitive Benchmarking: Reverse-engineer 30+ competitor products

Ⅱ. Concept Sketching

• Hand-drawn Proposals: 50+ draft designs by in-house artists

• 3D Mood Boards: Digital inspiration aligned with Milan/Paris Fashion Week

• Feasibility Review: Joint evaluation with engineering team

Ⅲ. Digital Modeling

• CAD Parametric Design: 0.1mm-precision modeling (SolidWorks/Rhino)

• Virtual Try-On: FaceGen simulations for diverse face shapes

• DFM Check: Identify 16+ manufacturability risks upfront

Ⅳ. Material Selection

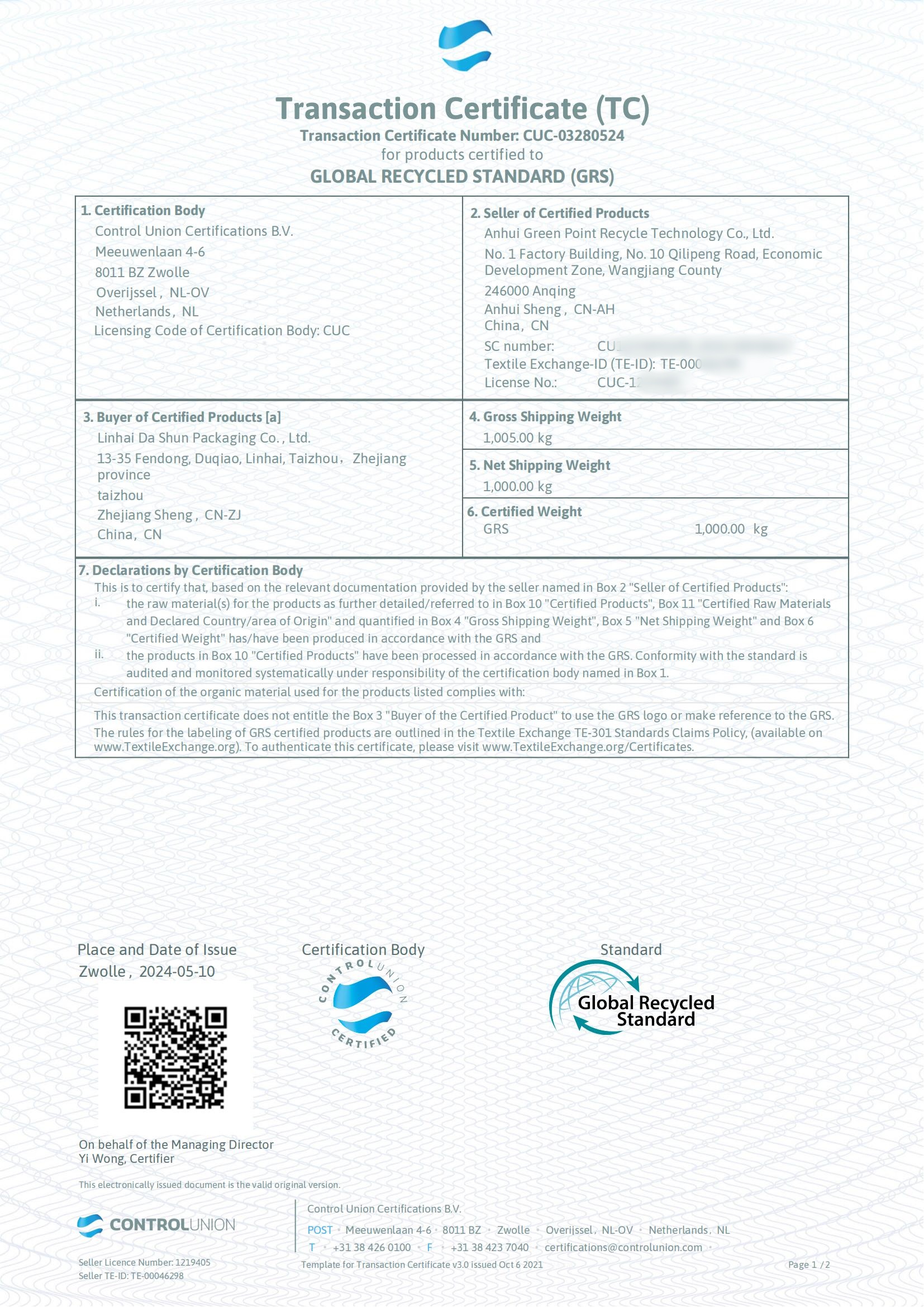

• Material library call: Choose from 200+ pre-certified materials (including GRS recycled options)

• Performance Tests: 5 essential tests (colorfastness/flex resistance, etc.)

• Cost Analysis: Compare Italian acetate vs. Japanese titanium alloys and many other material

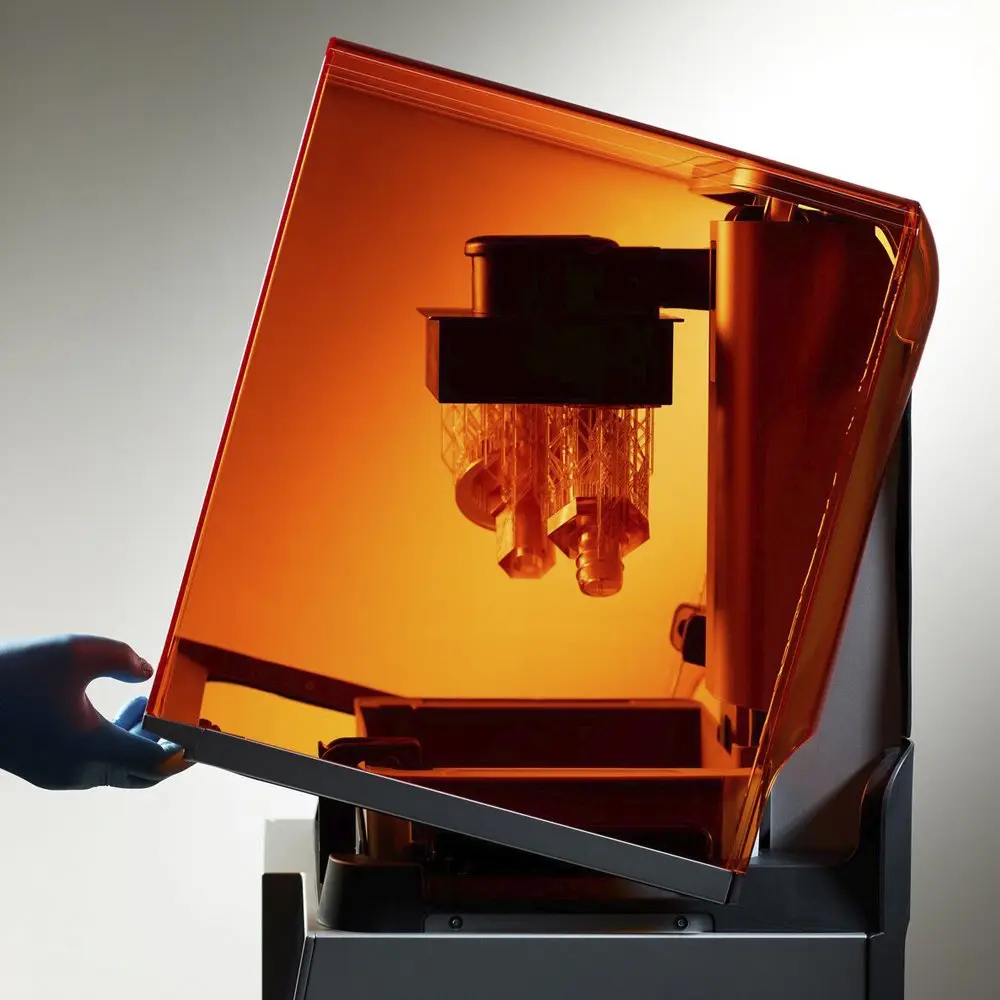

Ⅴ. Prototyping

• 3D Printing: Industrial-grade SLA functional prototypes, 3D-printed injection samples in 7 days (with custom colors) and metal frames in 14 days

• Handcrafted Samples: Artisanal acetate shaping by master craftsmen

• Assembly Verification: Check 8 critical fit points (hinges/temples, etc.)

Ⅵ. Design Refinement

• CAD Iterations: Adjust temple curvature/nose pad height based on data

• Mold Review: Coordinate injection molding plans with Vietnam factory

• Cost Rebalancing: Optimize price/performance ratio

Ⅶ. Production

• Mold Trial Report: 120+ parameter records (injection temp/pressure, etc.)

• Full Inspection: 100% QC check on first 500 units

Precision Manufacturing

Ⅰ. Metal Frame Production

We operate a mature metal frame production line capable of manufacturing 200+ titanium/stainless steel frame designs with:

• High-precision stamping: Ensures structural stability

• Reliable welding: Durable seams for long-lasting use

• Multiple surface treatments: Including electroplating, sandblasting, etc.

Our metal eyewear line produces 650,000 pairs monthly, supporting customization like engraving and color options.

Ⅱ. Acetate Frame Production

Our 70-Day Standard Lead Time with 100,000 Pairs Annual Capacity is Achieved Through:

• Precision sheet cutting: Tight tolerance control

• Climate-controlled curing: Guarantees dimensional stability

• Fine polishing: Delivers smooth, comfortable finish

Custom thickness and pattern embedding available.

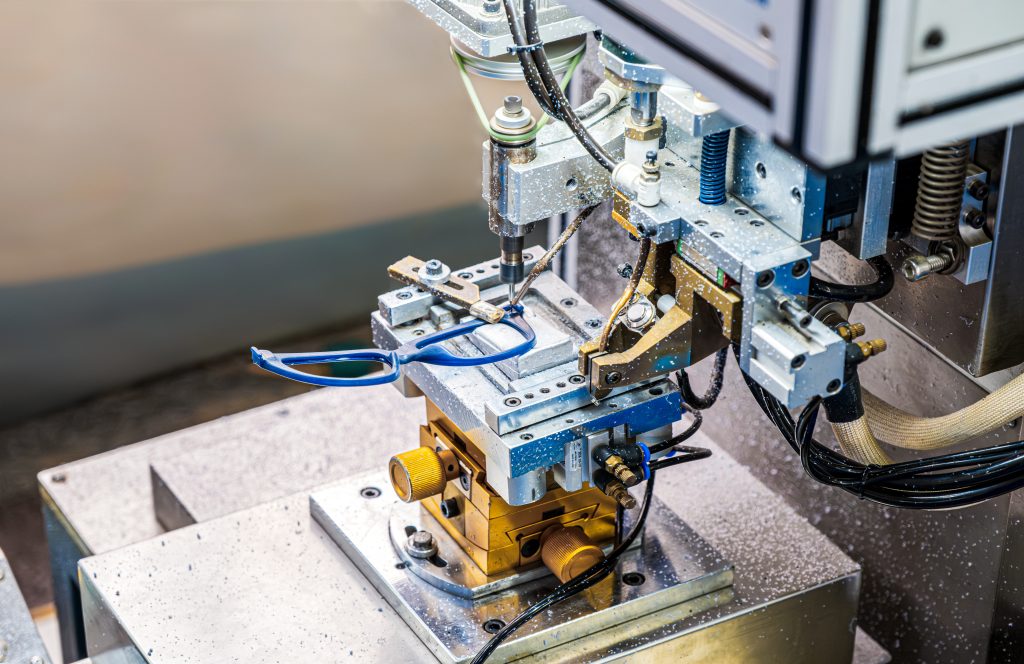

Ⅲ. Injection Frame Production

We specialize in high-precision injection molding for eyewear frames, offering:

• TR90 Ultra-Light Frames: Excellent elasticity & impact resistance

• Nylon Frames: High strength for sports designs

• Eco-Friendly Frames: Made with bio-based/recycled materials

Key Advantages:

• Monthly Capacity: 1,500,000 pairs for bulk order fulfillment

• Precision Molds: ±0.1mm dimensional accuracy

• Rapid Cycle Times: Optimized production efficiency

• Versatile Finishing: UV coating, laser engraving, etc.

All frames undergo EN ISO 12870 impact testing for durability and comfort.

Annual Capacity

Service

Ⅰ. Lab Testing

We conduct rigorous quality tests including:

• Salt spray testing: 72hrs exposure to verify corrosion resistance

• Hinge fatigue testing: 100,000+ cycles to ensure durability

• Prism accuracy testing: ±0.25D precision for optical clarity

All tests comply with ISO 12870 standards with detailed reports available.

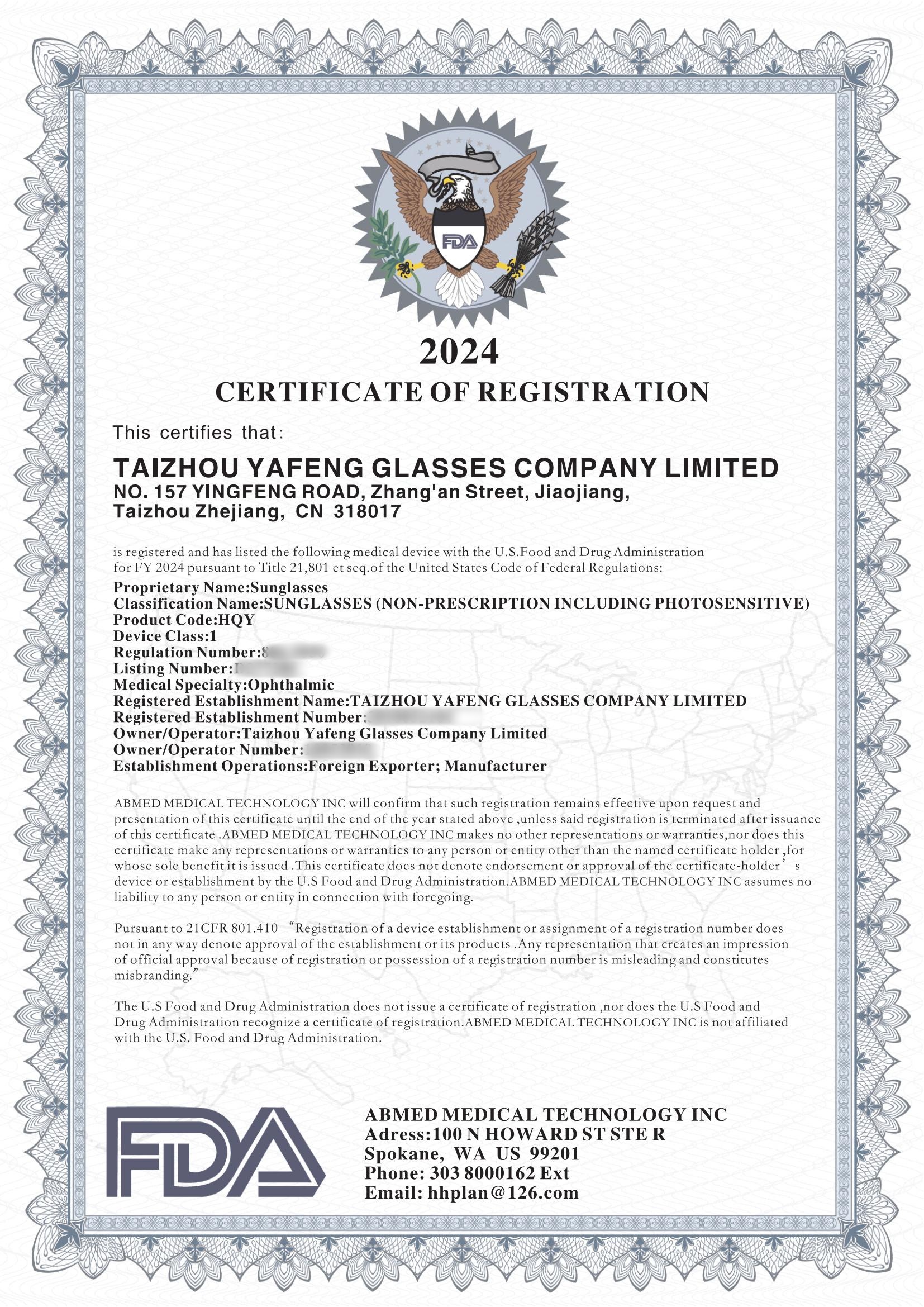

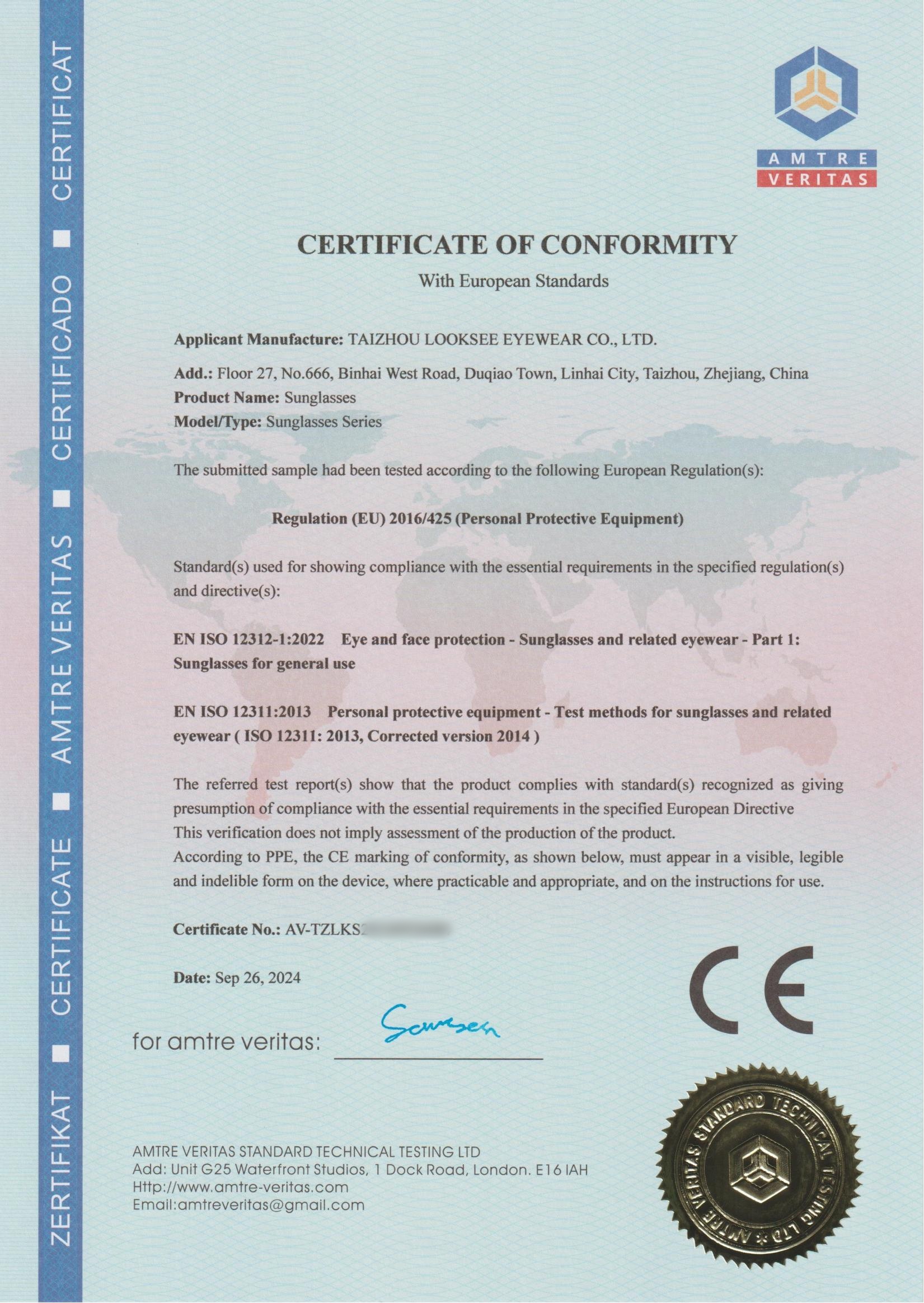

Ⅱ. Certifications

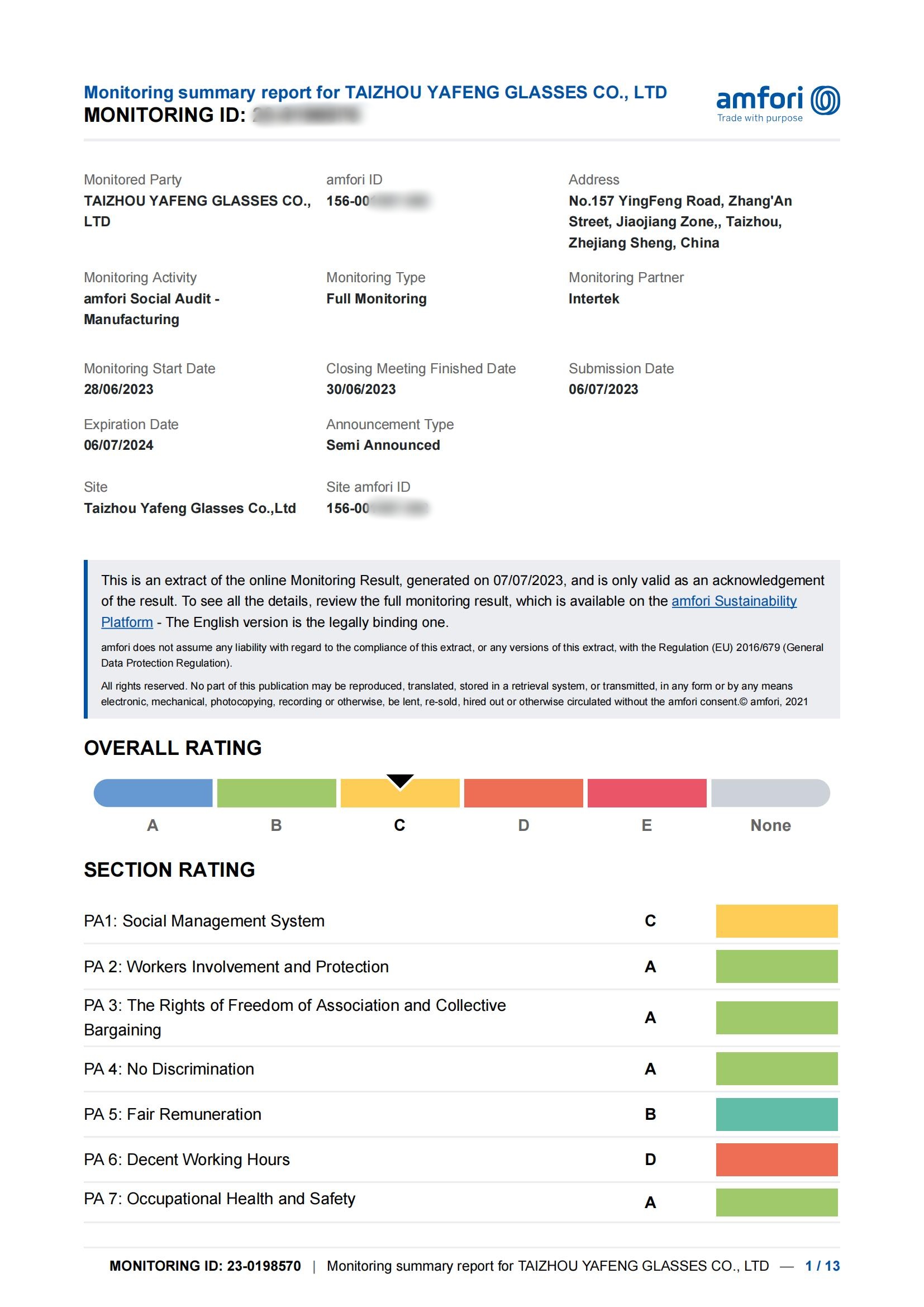

Our pre-approved certifications include:

• CE: EN ISO 12312-1:2013 compliance

• FDA: 21 CFR 801.410 impact resistance

• UKCA: UK conformity assessment

• BSCI/GRS/AS-NZS/ and other certifications

Certification packages available for faster market entry.

Ⅲ. IP Protection

We safeguard your designs through:

• Encrypted file transfers: Secure CAD data exchange

• Controlled access: Restricted production area entry

• Legal NDAs: Enforceable confidentiality agreements

Your intellectual property remains protected throughout production.

Logistics & Compliance

Ⅰ. Tariff-Optimized Production

Our Vietnam factory ensures 5-15% lower import duties for EU/US markets compared to China. Benefits include:

• Bulk order capacity with 30%+ increased output

• Full FDA/CE compliance matching our China facilities

Ideal for brands diversifying supply chains without compromising quality.

Ⅱ. Sustainable Packaging

We provide FSC-certified boxes (100% recyclable) with:

• Custom branding (logo/colors/QR codes)

• Eco-friendly materials (soy-based inks, kraft paper)

• Retail-ready designs (hang tags, barcode placement)

“From sketch to shelf” – we manage global logistics, certifications, and branding for seamless market entry.