In-House Lab

In-House Lab for you

- Performs requested tests and issues dated reports

- Archives both physical/electronic copies for 3 years

- Documents: Test date, order, style, and requester

Artificial Sweat Test Chamber

Artificial sweat testing simulates long-term wear by immersing eyewear in a pH 4.5-6.5 solution (lactic acid/NaCl mix) at 30°C. Samples soak for 24-168 hours in a climate chamber, then undergo:

• Nickel ion detection (atomic absorption)

• Coating adhesion check (tape test)

• Surface corrosion inspection

Compliance threshold: <0.5μg/cm²/week nickel release (EU REACH).

Salt Spray Test

Standard Test Types:

• Neutral Salt Spray (NSS)

Standard: ASTM B117 / ISO 9227

Solution: 5% NaCl, pH 6.5-7.2

Use: Baseline corrosion resistance check

• Acetic Acid Salt Spray (AASS)

Standard: ISO 9227

Solution: 5% NaCl + acetic acid (pH 3.1-3.3)

Use: Accelerated testing for decorative coatings

• Copper-Accelerated Salt Spray (CASS)

Standard: ISO 9227

Solution: 5% NaCl + CuCl₂ (pH 3.1-3.3)

Use: Fast evaluation of nickel/copper layers

Eyewear-Specific Applications:

✔ Frame Hinges (96h NSS for titanium alloys)

✔ Metal Temples (48h AASS for plating adhesion)

✔ Nose Pads (24h CASS for nickel release check)

✔ Decorative Elements (72h NSS for PVD coatings)

Complementary Tests:

▸ Cyclic Corrosion Test (salt spray + humidity)

▸ Artificial Sweat + Salt Spray Combination

Eyewear Frame Flammability Tester

An eyewear flammability tester evaluates frame safety by exposing samples to controlled flames (per ISO 12870). It measures:

• Burn rate (≤3mm/s for acetate)

• After-flame time (≤5 sec)

• Dripping behavior (no molten drops)

Critical for children’s/sports glasses, ensuring materials self-extinguish. Tests include horizontal (frames) and vertical (temples) flame exposure with calibrated butane flames (20±2mm).

Eyewear Frame Fatigue Tester

This instrument simulates years of wear through repetitive stress tests:

• 10,000+ hinge open/close cycles (ISO 12870)

• 5,000+ temple flexing motions (45° deflection)

• Nose pad compression tests (20N force)

Bridge Flex Tester

This device evaluates nose pad durability by simulating 10,000+ flex cycles (ISO 12870). It measures:

• Resistance to cracking

• Permanent deformation (<5%)

• Spring tension retention

Critical for metal/acetate frames to ensure long-term comfort. Tests run at 23±5°C with 30N force.

Eyewear Frame Alloy Analyzer

This XRF (X-ray Fluorescence) device identifies metal composition in seconds, detecting:

• Nickel content (EU REACH compliance)

• Titanium purity (Grade 2/5 verification)

• Plating thickness (μm-level accuracy)

Essential for:

• Material certification (ISO 5832)

• Nickel-free claims (<0.05%)

• Counterfeit detection

Portable models allow factory-floor checks.

Hinge Tensile Tester

A hinge tensile tester evaluates eyewear durability by simulating 10,000+ open/close cycles (ISO 12870). It measures:

• Hinge resistance (5-20N force range)

• Plastic deformation (<2° permanent bend)

• Failure points (spring/ screw fatigue)

Critical for metal/acetate hinges, ensuring 3+ years of daily use. Tests run at 60 cycles/minute with torque monitoring.

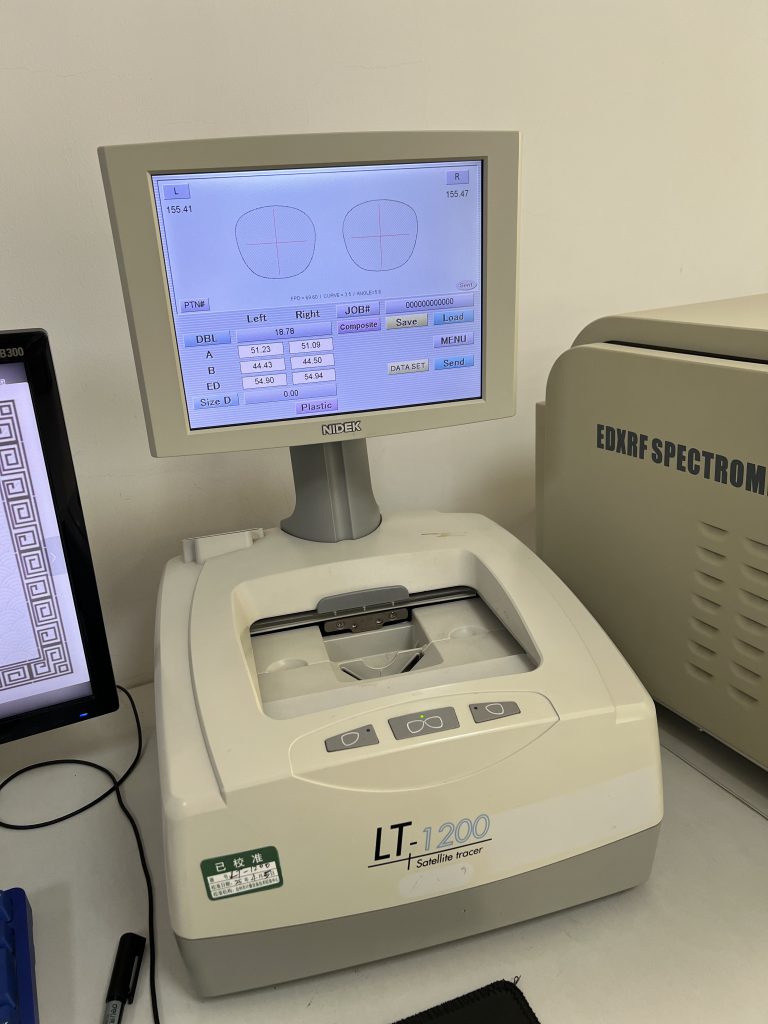

Lensometer

This precision instrument measures:

• Optical power (Sph/Cyl 0.01D accuracy)

• Axis orientation (±1° precision)

• Pupillary distance (PD)

Used for:

• Verifying prescription lenses

• Quality control in labs

• Frame alignment checks

Digital models auto-print specs and store data.

Prism Diopter Tester

Key functions:

• Base direction detection (0-360°±1°)

• Vertical/Horizontal prism (0-20Δ range)

• Prentice rule verification

Used for:

• Progressive lens QC

• Prism prescription validation

• Safety glasses ANSI Z87.1 compliance

Digital models auto-plot prismatic deviations.

Polarimeter

This device verifies polarized lens performance by:

• Measuring polarization efficiency (>99% for premium sunglasses)

• Detecting axis alignment (±2° accuracy)

• Identifying stress patterns in lens material

Critical for:

• Fishing/driving glasses QA

• Anti-glare lens certification

• 3D movie glasses production

Handheld models feature instant LCD results.

Standard Light Box

This calibrated viewing station provides consistent lighting for:

• Color matching (D65, CWF, UV light modes)

• Metamerism detection (material/coating batches)

• QC inspections (scratches/coating defects)

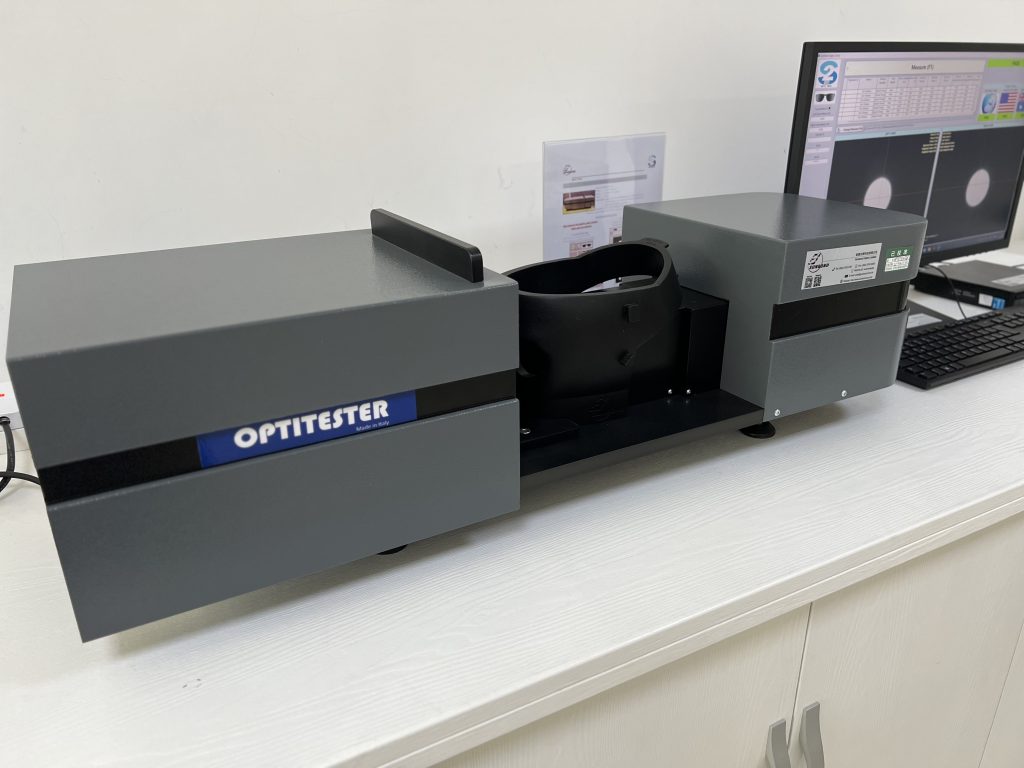

Sunglass Lens Uniformity Tester

This instrument maps optical consistency by scanning 9+ points on lenses to measure:

• Transmittance deviation (<5% tolerance)

• UV protection uniformity (380-400nm)

• Color gradient shifts (ΔE<3)

Critical for:

• Polarized lens QA

• Gradient tint verification

• Anti-reflective coating checks

Automated models generate heatmap reports.