YAFENG GLASSES QUALITY INSPECTION

Raw Material Inspection Standards

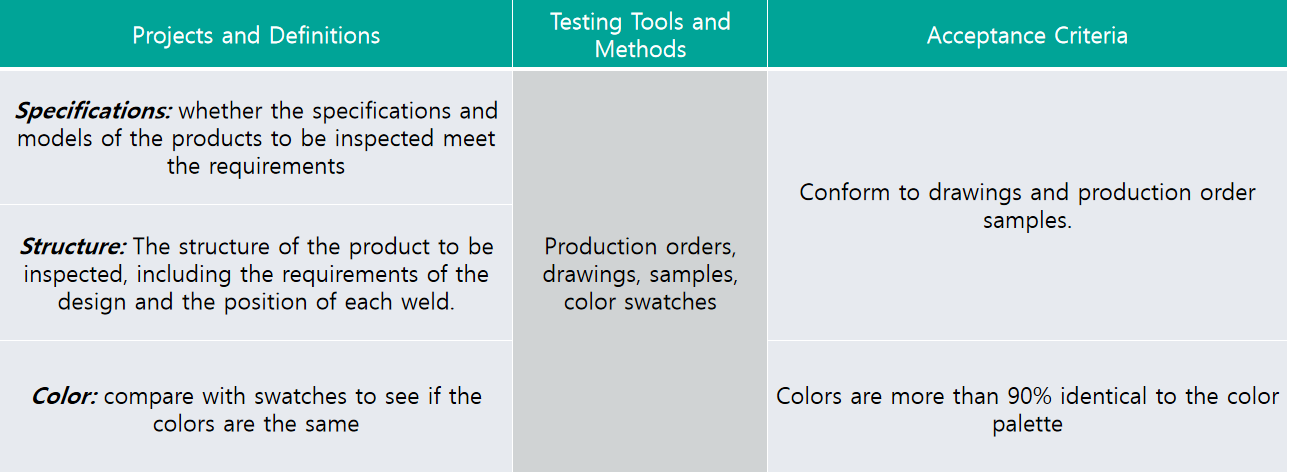

General Inspection Criteria

At Yafeng Glasses, we implement stringent quality control protocols for all incoming materials to ensure compliance with our exacting standards.

Material Verification:

Confirm that the material type, specifications, and dimensions match the purchase order requirements.

AQL Sampling:

Components: AQL 2.5 (Major defects)

Lenses: AQL 1.5 (Critical defects)

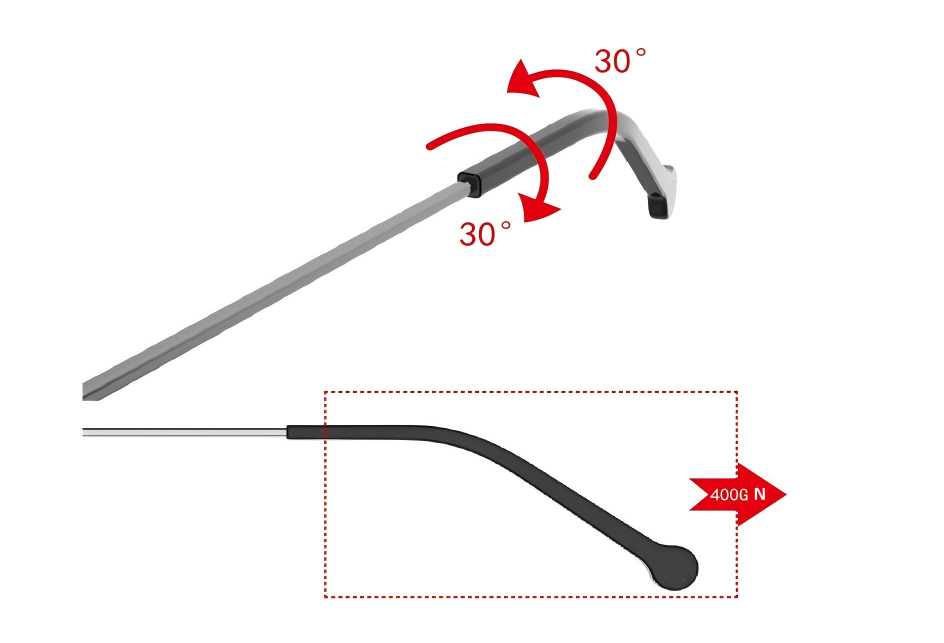

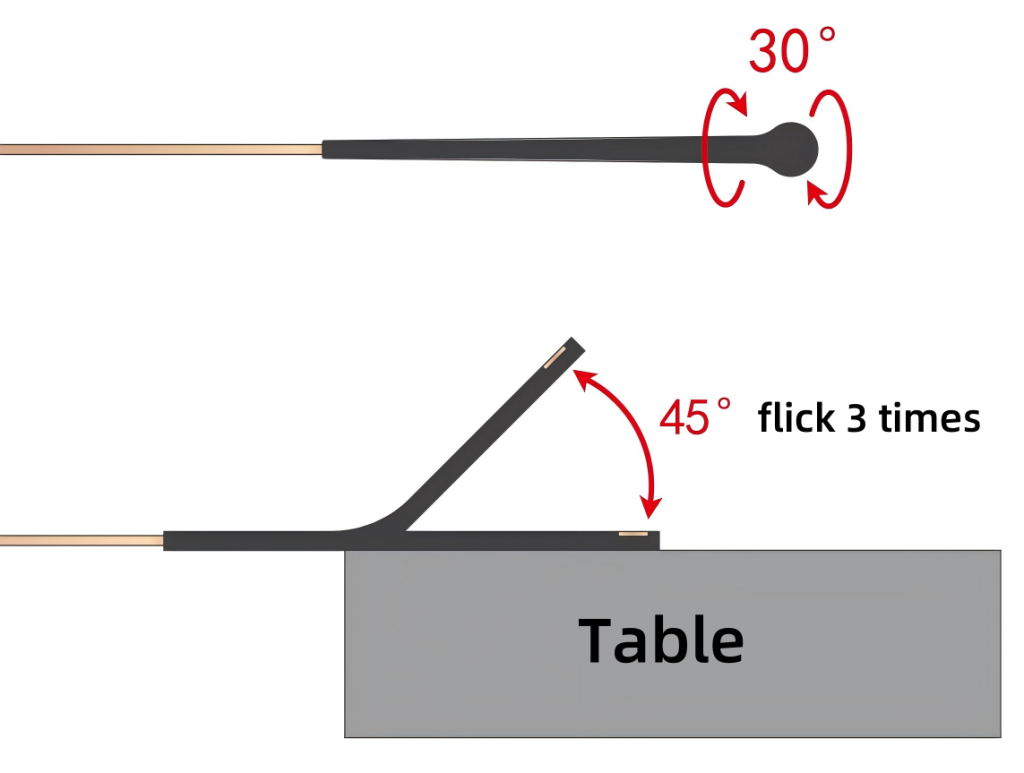

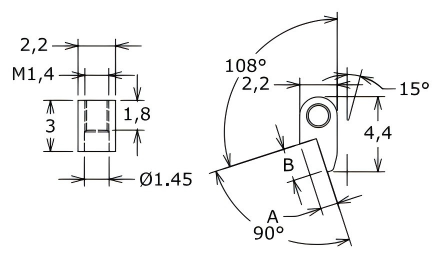

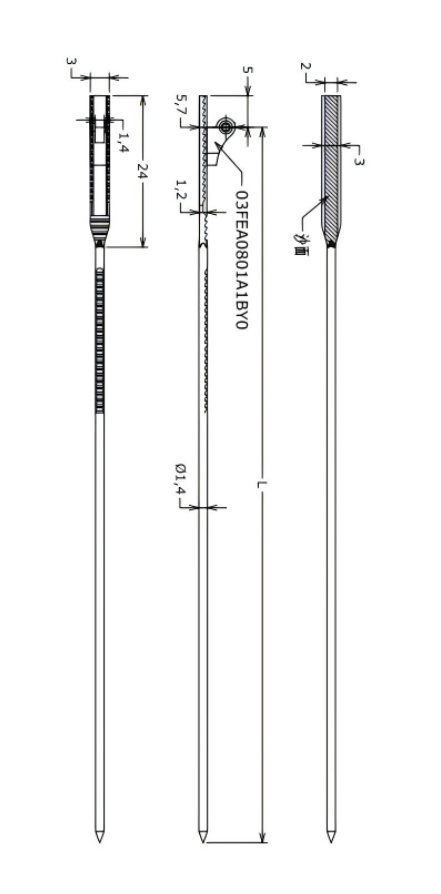

Copper Core Inspection

Process Inspection Standards

Comprehensive In-Process Quality Control

At Yafeng Glasses, we implement specialized QC checkpoints across all production stages:

- Soldering QC: Verifies joint strength (30N pull test) and alignment (±0.1mm tolerance)

- Metal Polishing QC: Checks surface smoothness (Ra ≤0.8μm) and defect-free edges

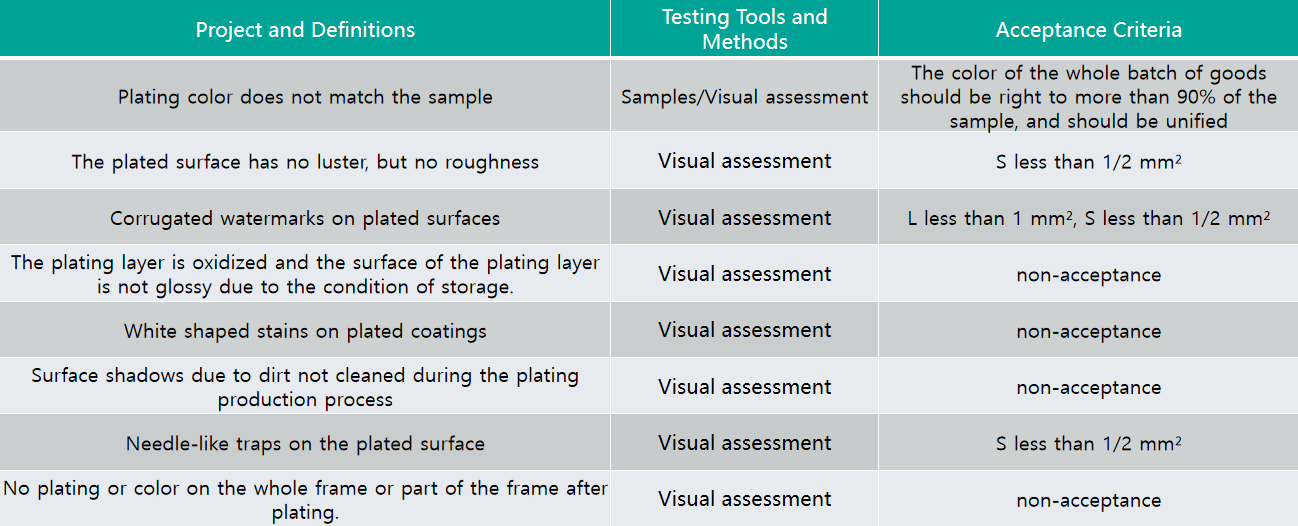

- Electroplating QC: Ensures coating adhesion (tape test) and salt spray resistance (48hrs)

- Acetate Polishing QC: Confirms gloss uniformity and structural integrity

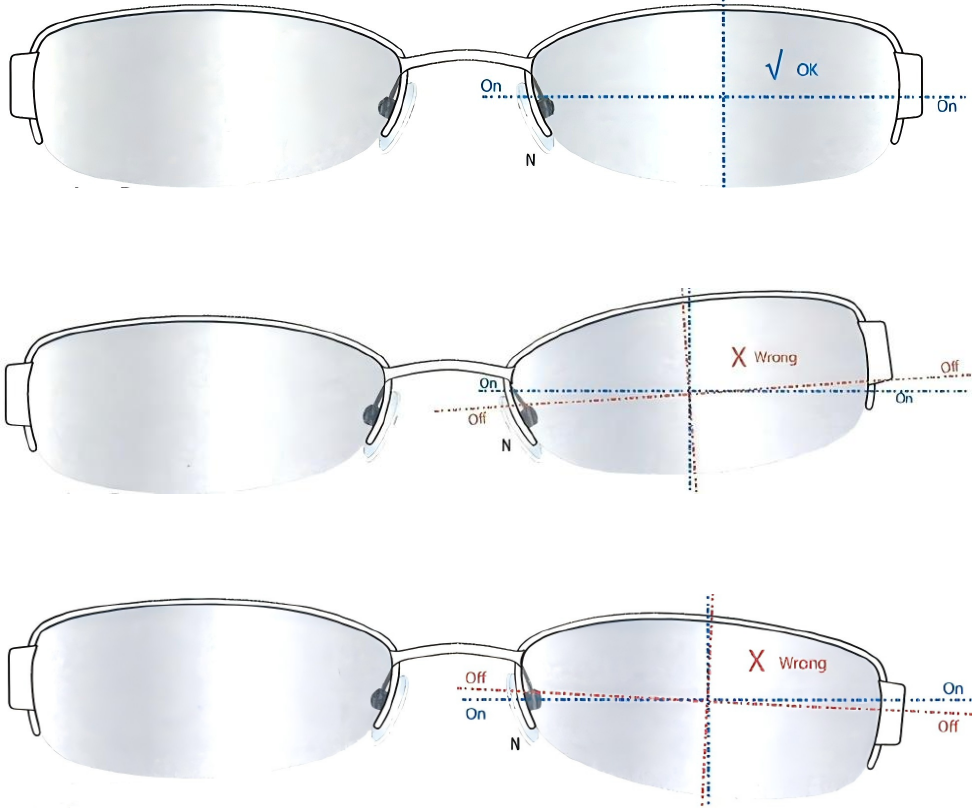

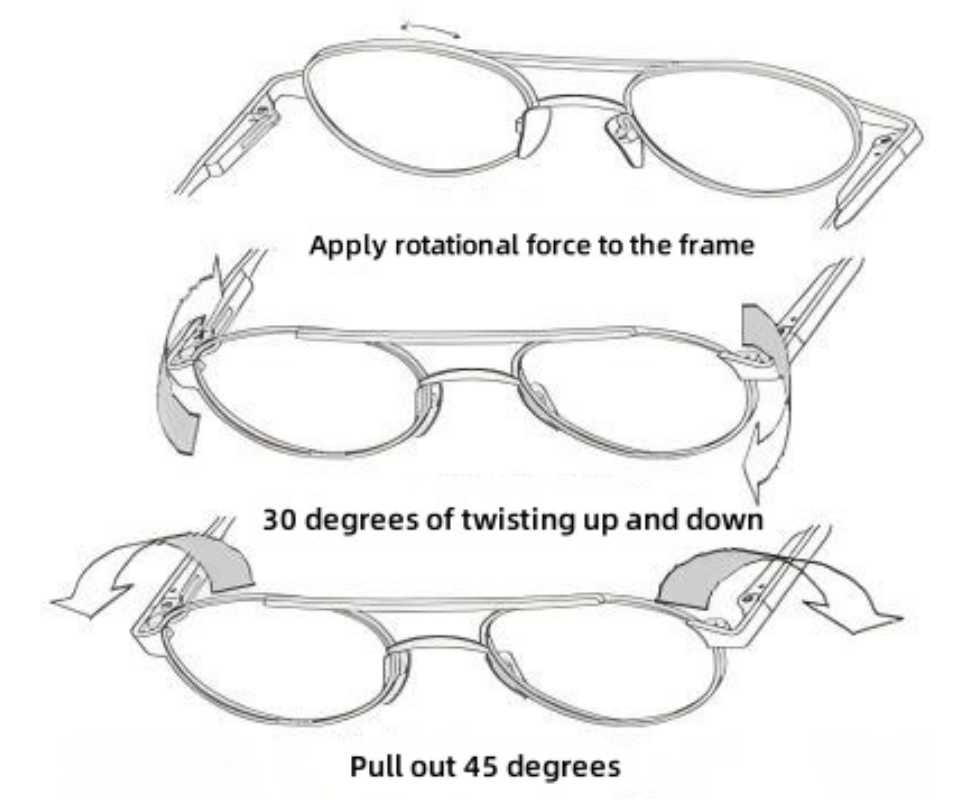

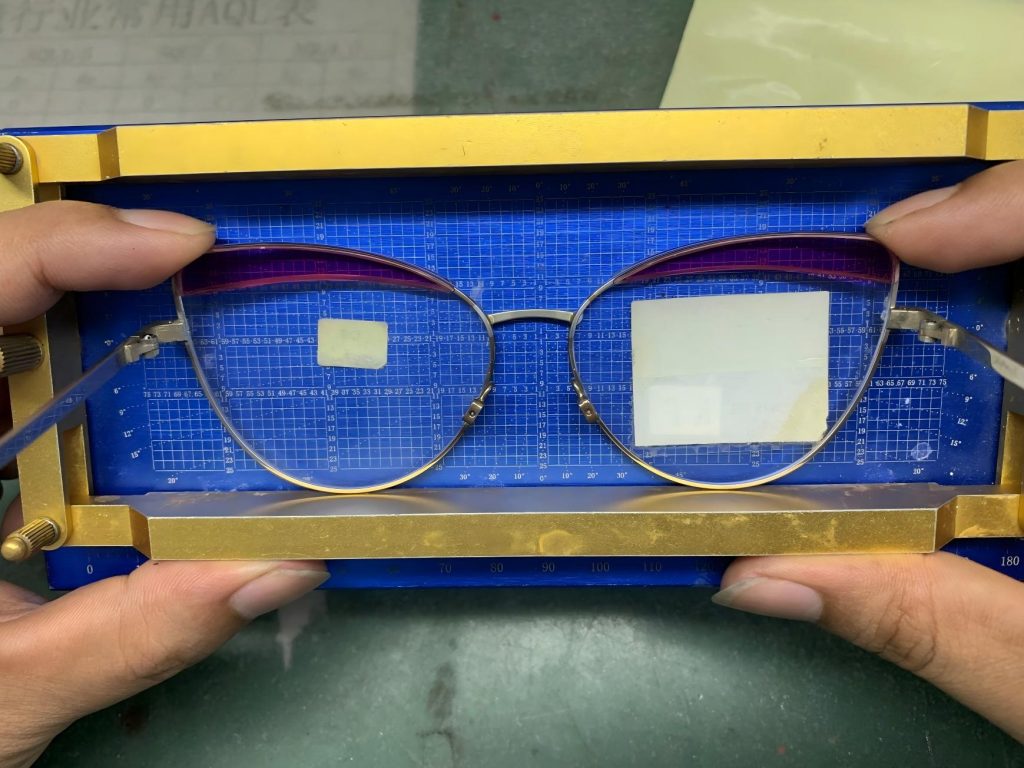

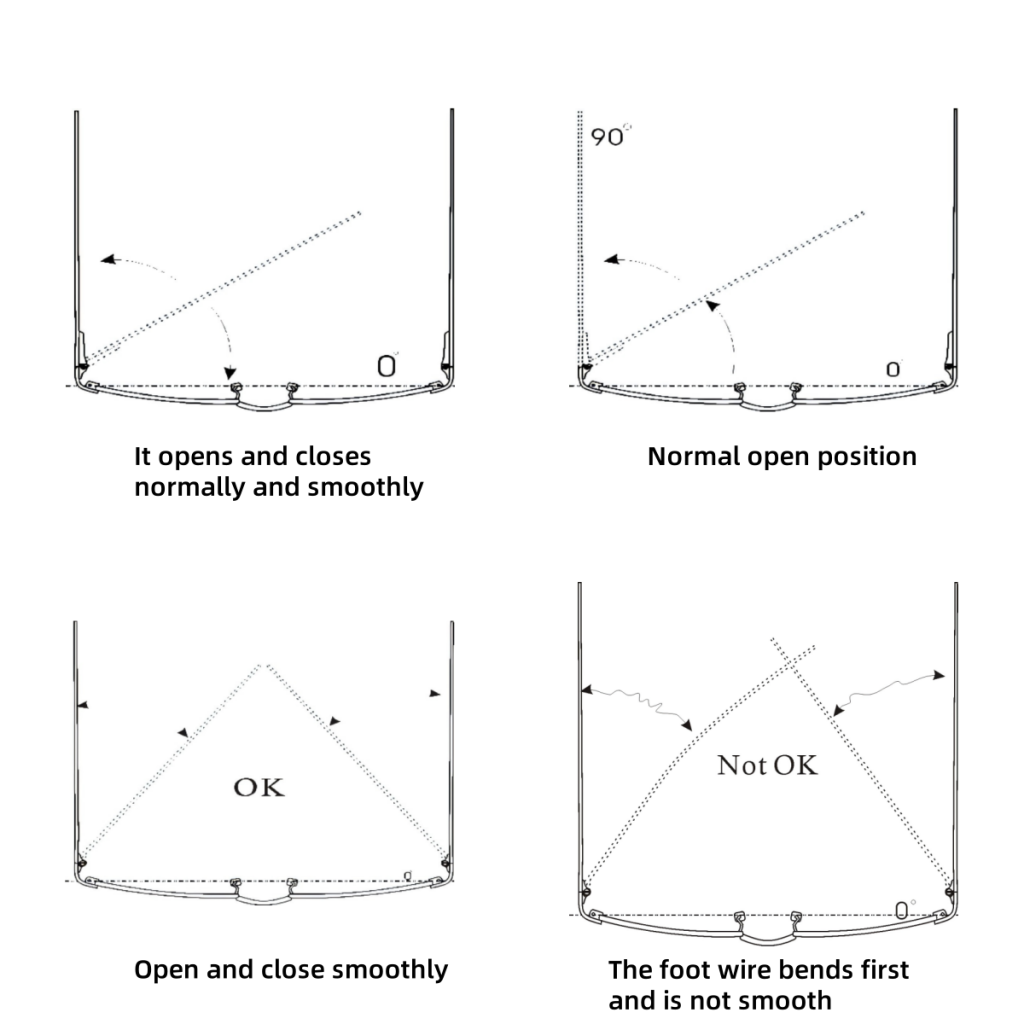

- Assembly QC: Validates hinge function and final fit

- and so on

Each checkpoint follows ISO 9001 protocols with real-time defect tracking.

For example, the following are the detailed quality control criteria for our electroplating process:

Finished Product Inspection Standards

Multi-Stage Finished Product QC Inspection

We implement rigorous quality checks at every production stage:

Surface Inspection: No scratches/dents (40W LED light verification)

Printing Accuracy: ±0.2mm alignment tolerance

Functional Testing: 5K hinge cycles, 30N temple flex

Cosmetic Audit: Color/Pantone match (ΔE≤1.5)

All inspections follow ISO 9001 protocols with digital traceability.